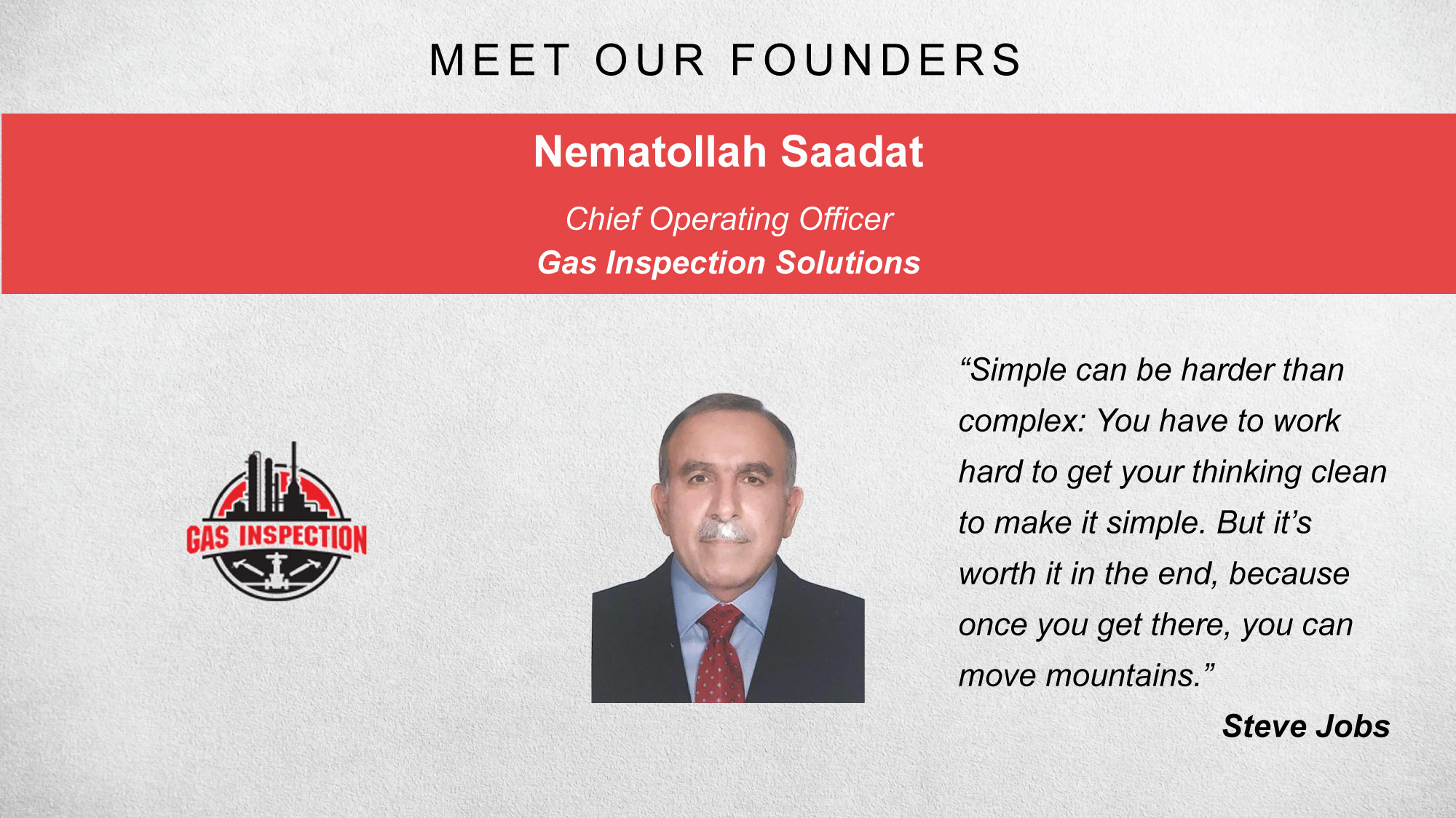

Meet Our Founders, Nematollah Saadat, Chief Operating Officer at Gas Inspection Solutions

Nemat is a civil engineer with over 33 years of experience in construction, related to oil & gas projects. He established a very successful construction company that serviced the Iranian oil & gas sectors, while he was the managing director of his own company. Moreover, not only he has managed and carried out some of the most crucial construction projects for power stations, buildings and hospitals but also as the civil constructor for famous companies such as Eni (Italy) and Sinopec Oil and Gas (China), he has done many civil works in their plants and roads in the field of oil & gas.

Having this rich expertise & experience and because of his interest in the fieldwork, as the COO of our company, Nemat has begun working in the fields of maintenance leveraging his insight & innovation.

During our Q&A with him, he provided many insightful information about the company and some of the most frequently asked questions in the fields of maintenance.

Please, first let us know about Gas Inspection Solutions briefly.

Gas inspection solution was established in 2020 with four shareholders that have more than 30 years of experience in oil and gas fields in Iran. Therefore, we chiefly rely on our background in the field. Moreover, we believe that we can launch our business with a new method of management in Canada regarding the maintenance of oil and gas plants, especially for the small and medium sized ones.

Can you tell us what are your main advantages and added values in your management and equipment in comparison with your competitors?

First of all, we are offering competitive prices and secondly we provide art maintenance management system, which offers predictive maintenance infrastructure, unified online reporting, automation, and basic asset tracking that causes all assets to run precisely on time.

Can you also explain how your QR code system works?

Since our system is computerized, our workers who have been trained and are authorized to perform maintenance tasks, first scan the QR code of asset on any smart device. The system then will show the status of the equipment and its repair instructions. Finally workers will request for service or status edit of the assets based on their current condition.

How does your system works correctly finding which parts need maintenance, and that their repaired or replaced ones will be available for preventing shutdown of the whole system.

Since Gas Inspection has partnerships with major vendors, it automatically orders parts before they are needed. For this purpose, the company allocates a special budget to provide replacements for critical parts; therefore, immediately after recognizing the problem by the QR code, the system will replace the out of work parts with new ones.

Regarding your software, equipment, and employees, do you think you can run the maintenance of big plants or small and medium sized ones?

In spite of our abilities we would rather work on small and medium size plants. Furthermore, we believe that with our experiences, facilities, and equipment it is better for us to not work on big plants at this time.

Add comments: